How Did Taiwan Become So Important to Semiconductors?

The story of the technology that started Silicon Valley growing up and moving out

This post is a special cross-post with the amazing substack Mostly Harmless Ideas. A huge thanks to Alex for the opportunity. And, for those that haven’t seen his substack, please check it out!

Taiwan is a modern marvel. A small island off the coast of China with a population slightly larger than Florida, Taiwan accounts for nearly a quarter of the world’s semiconductors.1 But, when it comes to the most innovative chips, Taiwan’s lead is even greater: of the most advanced semiconductors, those less than 10 nanometers thick, Taiwan produces a whopping 92% of global output.2 In management-consultant speak, Taiwan has a market share in the most advanced semiconductors slightly greater than Google’s market share of web searches.

But, having a large market share in semiconductors is not like having a large market share in soap, sawblades, or SUVs. Semiconductors are fundamental to all modern electronics. From laptops to drones, semiconductors are the backbone of everything electronic. As the image below shows, a single iPhone can require over twenty different chips. Not surprisingly, as the car market’s performance during the pandemic demonstrated, withholding semiconductors brings industries to a sudden crash. And this dynamic doesn’t just apply to consumer goods: defense departments also need semiconductors for their increasingly technology-driven approach to warfare. Consequently, dominating the semiconductor market gives Taiwan enormous importance on the global stage.

All this raises a lot of questions. Semiconductors were literally the technology that started it all, the foundation of the Valley. How did they leave California? And, once they left, why Taiwan, of all places? Can’t anyone catch up? Though a history of Silicon Valley would be far too much for one post, I try to shed light on these questions in the post below.

In the beginning, there was Fairchild

While we tend to use “semiconductor” to refer to all manner of chips and circuits, understanding semiconductors’ migration from California to Taiwan requires being more precise about the word's meaning. Back in the 1940s and 50s, the word “semiconductor” would have meant the same thing you learned back in high-school science: a material that has electrical conductivity between that of a conductor (like copper) and an insulator (like rubber). It would not have connotations of electronics, which largely relied on vacuum tubes at the time (e.g., the enormous ENIAC computer built in 1946).

William Shockley changed all this. For better and worse, Shockley was the archetypal scientist of the Oppenheimer era. Born in 1910, he attended CalTech and MIT before serving in WWII, where he had the horrible task (though one I fear he did not think was quite so horrific) of performing the calculation that estimated the number of Japanese soldiers that would likely need to die before a surrender, providing the justification the American military needed to bomb Nagasaki and Hiroshima.3 Once the war was over, he moved to Bell Labs, the leading technology company of its day, employing, among others, John Bardeen, who also worked on semiconductors and would be one of four people to win two Nobel prizes.

During his time at Bell, Shockley theorized a “solid-state valve” that would pass electricity if plugged into a battery. At a very simplistic level, Shockley created a transistor that would switch on when the current flowed and off when it didn’t. Shockley could control this current by altering semiconductive materials (first geranium, later silicon), turning the transistors on and off in the zero and one binary that forms the basis of all digital goods. 4

Though it would take two years to refine and test, he ultimately succeeded in building his valve, creating the first “semiconductor,” as we think of it today. Though not a businessman by nature, Shockley recognized that his innovation could replace vacuum tubes and decided to strike out on his own, creating a business named after himself in 1955.

Shockley proved an excellent eye for talent, hiring some of the most brilliant engineers in the world to work for him, including Gordon Moore, who would become famous for Moore’s Law, and Robert Noyce, who would found not one but two leading semiconductor firms. And he would move them all back to his hometown of Mountain View, California.

But, Shockley was not a likable manager and was wildly disliked by the young college graduates he hired. So, after two long years, the “traitorous eight” left Shockley and started their own firm, Fairchild Semiconductors, in 1957. 5

It’s hard to oversell the legacy of Fairchild; not only did it create the first integrated circuit, but it spawned dozens of spinoffs, creating a family tree that includes most of the companies and venture capital firms we associate with Silicon Valley.6 The root of these achievements was the planar method, developed in 1959, which meant that instead of putting transistors into, rather than on top of, the germanium. Effectively, this meant more reliable production of quality semiconductors and the ability to shrink them. By 1960, Fairchild was making semiconductors with four transistors on them and raking in over $130 million a year. Though a far cry from the 15 billion transistors in the iPhone 15, Fairchild’s leap set the process in motion to make the achievement possible. 7

Some months later, Robert Noyce realized that the Planar Process enabled multiple transistors on a single piece or “chip” of silicon, creating the “integrated circuit” or “chip” that we think of today when we use the term “semiconductor.” At the same time, using a very different approach, Jack Kilby, an engineer at Texas Instruments, also developed an integrated circuit, making Texas Instruments and Fairchild essentially the entire integrated circuit market. However, Fairchild had much better operations and lower costs, making it the only profitable manufacturer throughout the 1960s. Still, Kilby won the Nobel prize in 2000, which would have been shared with Noyce had he not passed away ten years earlier.8

But who was buying all these semiconductors? The US government. In 1965, Noyce estimated that 95% of their sales were for military and space operations.9 Robert McNamara, the famous Defense Secretary, was desperate to modernize the US military, particularly as he tried to limit civilian deaths in Vietnam by using guided missiles, which were, of course, powered by semiconductors.

By this time, however, the semiconductors were starting to get noticed by the rest of the world. The USSR quickly recognized the need to produce semiconductors to stay militarily competitive and had unsuccessfully attempted to copy US technology for years. More importantly for the industry, however, Akio Morita, the brilliant Japanese entrepreneur, had taken notice of the US electronics boom and was bringing it back to Japan.

Japan takes off!

In the wake of World War II, Japan had been heavily bombed, leaving little in terms of industry. However, it did have an American military presence, which brought American publications, and not just the New York Times. Journals like Bell System Technical Journal, Physics Review, and others began floating around Tokyo, creating an interest in electronics within the country.10

Morita was one of these interested men. Though expected to take over his father’s soy sauce business, Morita loved what he saw in mathematics and technology and sought to make a career in it. He opened a repair shop in 1945, at the age of 24, and eventually began making electronics under the name “Sony.” However, he licensed the right to build transistors and semiconductors from American firms to make these electronics. At the time, American firms didn’t see much value in personal electronics - the military was the big buyer - so they licensed their technology cheaply, allowing Sony first to make cheap radios and then become the powerhouse we think of today.11

At the same time, back in the US, semiconductor superstars Noyce and Moore were becoming fed up with Fairchild. Fairchild, having been formed as a subsidiary of Fairchild Camera to generate the initial capital needed to start the business, had not given equity to its employees. Noyce and Gordon wanted a greater share of the money they were bringing in.

In 1968, Noyce and Gordon left Fairchild to found Intel. In doing so, they would bring two significant changes to the industry. First, they would give equity to employees, creating the Silicon Valley model we think of today. Second, instead of focusing on integrated circuits, they would focus on dynamic random access memory (DRAM). More simply, instead of concentrating on chips that performed logic, they focused on memory applications. Still, they relied on the Pentagon for their initial paychecks, but as computing boomed, so did Intel.

It was during this period that Moore coined the famous “Moore’s Law” phrase. He recognized in 1965 that the number of transistors on a semiconductor doubled yearly in the 1960s. By the 1970s, he had revised this to be every two years. Still, his observation distilled the rapid advancement in technology the industry made during the period. 12

However, these advancements were no longer confined to American shores. Firms like Hitachi and Mitsubishi began to manufacture semiconductors as well. And, by the 1980s, Japan had brought the price of semiconductors down so low that American firms, with their very high labor costs, could not compete. By the mid-1980s, the Defense Department began to worry about the industry, trying to find a way to ensure that the sector stayed alive.13 Firms began to close rapidly, and Americans started to fear that they would be unable to compete. While Intel would famously pivot to personal computers under the legendary CEO Andrew Gove, the rest of the industry would continue to struggle. Worse, new countries, like Korea, and a small, recently born country off the coast of China would begin to emerge.

The rise and rise of Taiwan

Taiwan’s success in semiconductors can be traced back to a single man: Morris Chang. Chang was born in mainland China in 1931 but left at 18 to study at Harvard University. Though he enjoyed studying the humanities, he decided they would limit his career prospects. While some might have simply changed majors, he was apparently very concerned about the humanities restricting his career prospects, so he switched both majors and universities, moving to MIT where he majored in electrical engineering, completing his bachelor’s and master’s degrees, though failing his PhD defense.

Undeterred, he moved on to Bell Labs to make transistors. As it turns out, his pivot from the humanities was justified, and he excelled at Bell. Bell paid for him to go back to school to get a PhD at Stanford and promoted him up the chain until he was a candidate for CEO. But, unlike the previous characters in this story, Chang was not promoted for his brilliant ideas but for his managerial efficiency. He was amazingly good at running semiconductor plants.

While this may sound trivial, it’s difficult to emphasize just how hard manufacturing semiconductors is. Because chips are so small, any dust particle, excess of light, or temperature fluctuation completely wrecks them, making production in “fabs” costly and challenging.

In 1979, however, the industry experienced a breakthrough developed by Lynn Conway and Carver Mead. Conway had been working at IBM, where she had been fired and undergone a gender transition. She arrived at Xerox in 1973 and spent a lot of time thinking about the company’s labyrinth manufacturing processes. Working in Xerox’s legendary Palo Alto Research Center, she met Mead, who had been a friend to Gordon Moore. Together, they came up with the Mead-Conway process, which outlined a set of instructions that meant manufacturing could be standardized. Instead of companies both designing and manufacturing semiconductors, the Mead-Conway Revolution explained how a set of designs could be fed to a manufacturing plant to develop semiconductors in a standardized way. In essence, this enabled a division of labor between firms that designed semiconductors and those that manufactured them.14

Chang recognized this revolution and saw it as a “Gutenberg moment” for semiconductors. He pondered the idea of a foundry, where customers could send designs for chips and have them manufactured. However, despite his managerial skills, TI was not impressed and passed him over for CEO. He floundered for several years before getting an incredible, life-changing call in 1985: K.T. Li, the Finance minister of Taiwan, wanted to speak to him.

Li was a Cambridge-educated economist who had come to Taiwan in 1948, having been born on the mainland and rose to take on several high-profile roles in the economy of Taiwan by the mid-1960s. At the time, Taiwan was a poor, agrarian economy under martial law, and the country, like many other Asian countries, saw electronics, specifically semiconductors, as the solution. Unlike other Asian countries, Taiwan had Li and Li had a plan. In reaching out to Chang, he found an unbelievably capable leader to build the Taiwanese base and promised immense backing. To create the Taiwan Semiconductor Manufacturing Company, better known as TSMC.15

Chang used these funds to build his foundry based on the Mead-Conway principle, resulting in the first foundry dedicated to manufacturing, not designing, chips. In so doing, Chang essentially introduced specialization into the industry. Rather than having to both design and manufacture chips, companies like ARM and Nvidia, who make exceptionally advanced chips, could now focus their efforts on design and reliably manufacture the results at scale in a low-cost location.

Though TSMC has become the world’s manufacturing powerhouse, Taiwan also boasts United Microelectronic Corporation (UMC), the second-largest contract manufacturer of semiconductors. Between the two companies, Taiwan has completely dominated semiconductor manufacturing. Beyond the sort of historical contingencies of the characters involved, four key economic concepts shed light on why Taiwain was so successful:

First-mover advantage: While Taiwan was not the first Asian company to begin making semiconductors, it was the first to focus on a foundry, not designing chips or integrating them into electronics, giving it a unique niche.

Specialization: By focusing exclusively on manufacturing, Taiwan’s firms can focus on creating more, better chips. Consequently, their quality control and efficiency are much higher than the rest of the world. Given the difficulty of manufacturing semiconductors, it’s nearly impossible for anyone to imitate.

Wage differentials: Being an agrarian economy, Taiwan’s initial labor costs were very, very low, even relative to other non-US companies, such as China. Consequently, especially in the early years, it could undercut competition.

Agglomeration: Economists such as Michael Porter have noted the counterintuitive phenomenon that competitors in an industry will often be physically located in the same place. This occurs because resources, namely talent, also pool there, making it most efficient for the entire industry to be in one spot - this is true of shoes in Italy, banks in New York, and semiconductors in Taiwan. By having all the top manufacturing talent in one place, coupled with all the supply chains set up to deliver to Taiwan, it’s tough to unseat Taiwan’s dominance in the space.16

By the 1990s, these factors became self-reinforcing, and Taiwan rose to the top of the leaderboards. Though Intel would pivot to making and manufacturing semiconductors for Windows PCs, the boom in personal electronics and advanced computing would continue to supply TSMC and UMC with plenty of business. ARM, founded in the UK in 1990, would come to design some of the most highly advanced chips of the era without ever opening a manufacturing plant, using TSMC to manufacture its goods. Similarly, American firms like Intel began to wind down their manufacturing, outsourcing it to Taiwan for lower costs and better quality.

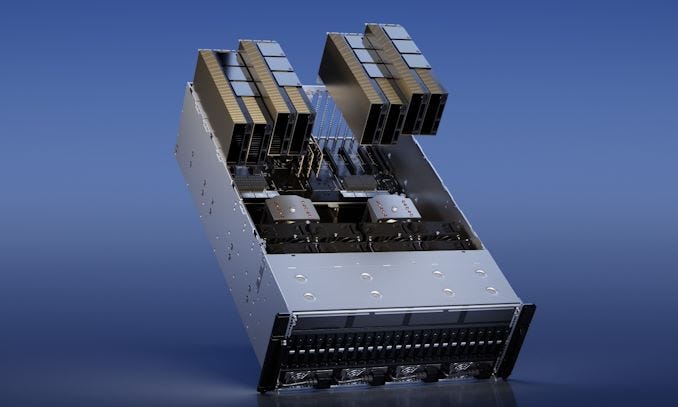

Though this trajectory alone would have been enough to put Taiwan in the lead, the computer industry experienced another change that supercharged Taiwan’s leadership: artificial intelligence. While much of the statistical know-how for advanced machine learning and artificial intelligence existed way back in the 1950s, these formulas were largely dormant due to a lack of data and computing power.17 But, by the 2000s, data and data storage had grown immensely. And computer scientists had realized that semiconductors for graphics, called GPUs (graphics processing units), were far better than traditional processing units (CPUs or central processing units) at simultaneously performing millions of small calculations.

This realization led to a boom in GPUs, led most notably by Nvidia, today the world’s third most valuable company. To perform complex machine learning - everything from Netflix’s search algorithm to Alexa - semiconductors of the type only TSMC can produce became essential. With the boom of Generative AI, even more sophisticated chips are required. As electronics companies like Apple look to create GenAI applications for local devices (e.g., iPhones), TSMC’s value will continue to grow. Though only worth about $50B in 2010, today, TSMC is worth nearly $800B, approximately 16 times more than Ford Motors and three times more than Netflix.

The road ahead

All of this creates an enormous geopolitical headache for the US government. With rhetoric between China and Taiwan (and China and the US) heating up, the semiconductor industry sits in the eye of the storm. The brief lapse in semiconductor manufacturing during Covid showed that a slight hiccup in production could bring even the market for cars to a standstill: what a Chinese takeover, or worse, an actual war, would create is almost unimaginable.

But agglomeration is a powerful force to overcome. While a Latin American country could make the same maneuvers as Taiwan did 50 years ago to leapfrog production and unseat Taiwan as the industry's base, manufacturing standards are now so high that doing so is increasingly challenging. In essence, the first-mover advantage and benefits from specialization are no longer enough to get ahead, so the wage differential is simply not enough to compete on.

Government investment is the obvious solution, which is precisely what the Biden Administration did with the CHIPS ACT, passed in 2022. The Act sought to invest $50B into US chip manufacturing through subsidies as part of the Administration’s industrial policy to boost jobs and lower exposure to China. Though US companies like Intel benefitted, leading non-US companies like TSMC benefitted the most, as they are now simply building factories on US shores. So, in essence, the US government is paying the difference in the wage differential, but even then TSMC and others benefit from their knowledge and specialization. In short, Taiwan’s leadership in advanced semiconductors appears set to continue for the foreseeable future.

Florian Zandt, “Where Can the Most Chips Be Manufactured?,” Statista Daily Data, December 5, 2023, https://www.statista.com/chart/31371/distribution-of-global-semiconductor-fabricating-capacity/.

Sarah Ravi, “Strengthening the Global Semiconductor Supply Chain in an Uncertain Era - Semiconductor Industry Association,” Semiconductor Industry Association, May 11, 2021, https://www.semiconductors.org/strengthening-the-global-semiconductor-supply-chain-in-an-uncertain-era/.

Giangreco, Dennis M. "Casualty projections for the US invasions of Japan, 1945-1946: Planning and policy implications." Journal of Military History 61 (1997): 521-582.

Langlois, Richard N. The Corporation and The Twentieth Century: The History of American Business Enterprise.Princeton University Press, 2023, pg 361.

Bauer, Luc Olivier, Wilder, E. Marshall. The Microchip Revolution: A Brief History. Amazon. 2020, pg 15.

Computer History Museum, “Fairchildren - CHM,” CHM, October 8, 2019, https://computerhistory.org/fairchildren/.

Shankland, Stephen. “Apple’s A15 Bionic Chip Powers iPhone 13 With 15 Billion Transistors, New Graphics and AI.” CNET, September 14, 2021. https://www.cnet.com/tech/mobile/apples-a15-bionic-chip-powers-iphone-13-with-15-billion-transistors-new-graphics-and-ai/.

Miller, Chris. Chip War: The Fight for The World's Most Critical Technology. Simon and Schuster, 2022, pg 16.

Ibid, pg 29.

Ibid, pg 46.

Ibid, pg 3.

Babbage. “Moore on Moore.” The Chip Letter (blog), January 21, 2024. https://thechipletter.substack.com/p/moore-on-moore. In general, this is an excellent piece on Moore’s Law for those who are really curious.

Miller, Chip War, pg 99.

Ibid, pg 137.

Ibid, pgs 163-166.

Porter, Michael E. Competitive Advantage of Nations: Creating and Sustaining Superior Performance. Simon and Schuster, 2011.

Babbage, “Neural Networks and the Origins of Modern Computing,” The Chip Letter (blog), September 17, 2023, https://thechipletter.substack.com/p/neural-networks-and-the-origins-of.

What a fascinating read, it’s been a while since I kept reading all the way to the end. Thank you 🙏

Do you mean martial law?